Easy,

Fast,

Effective

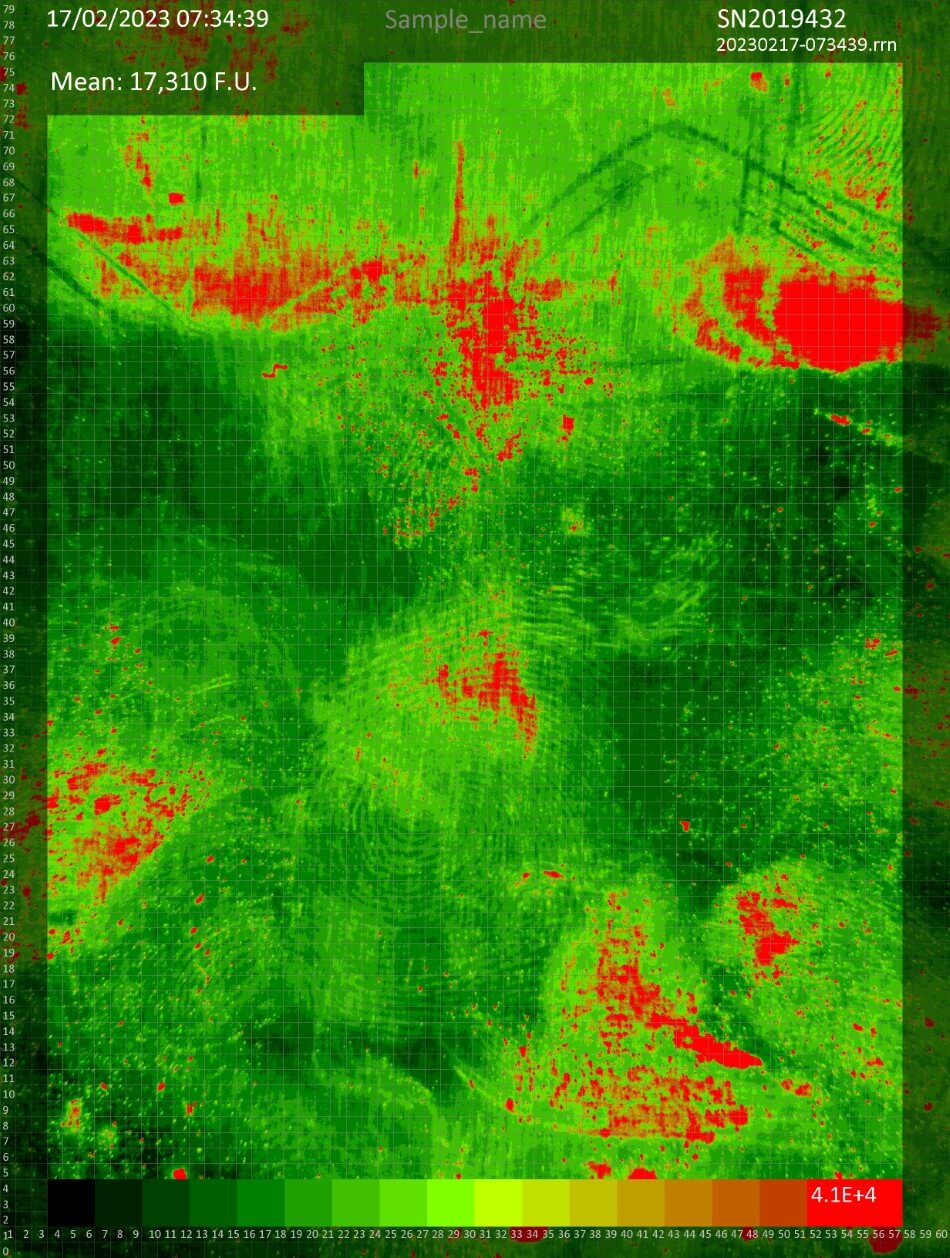

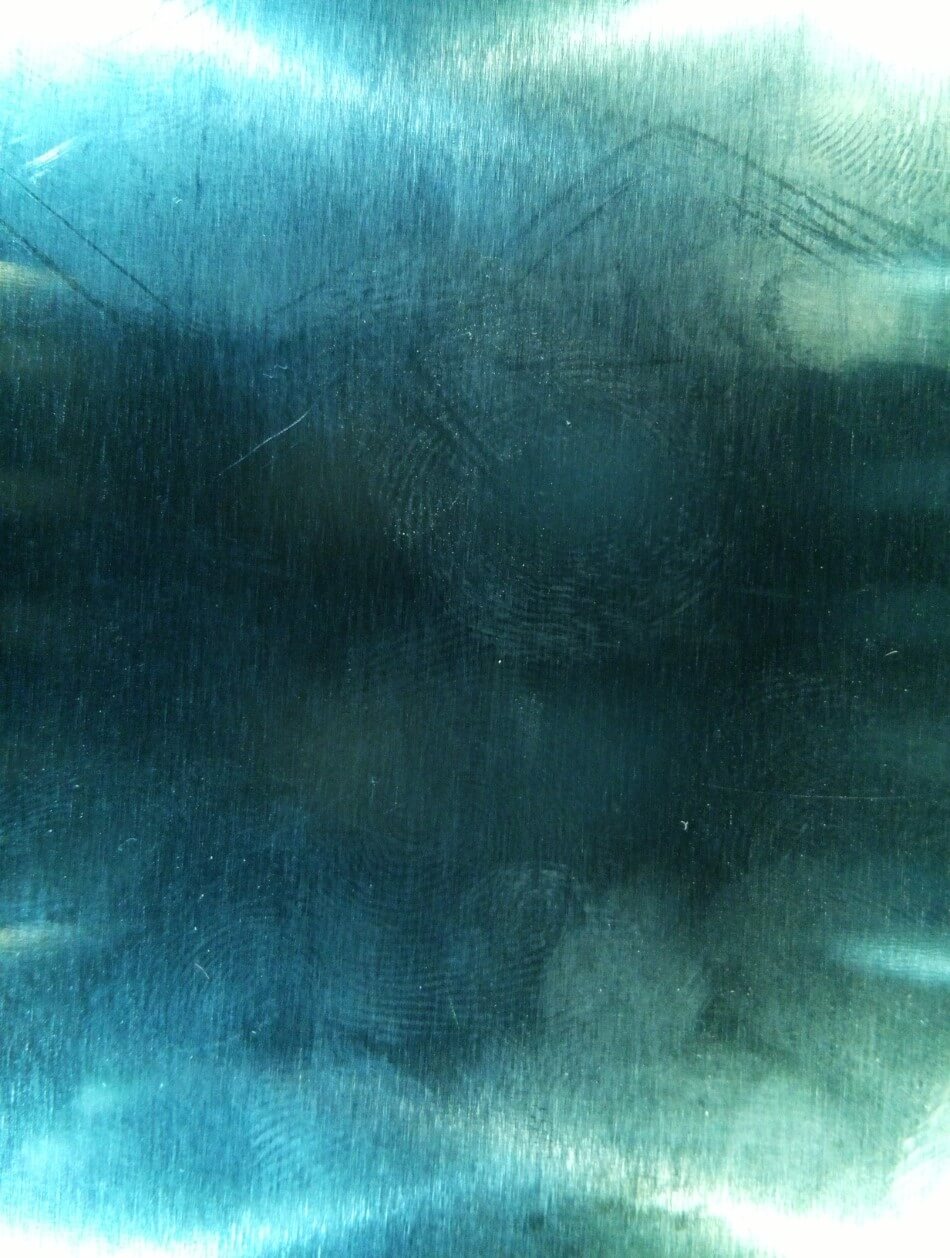

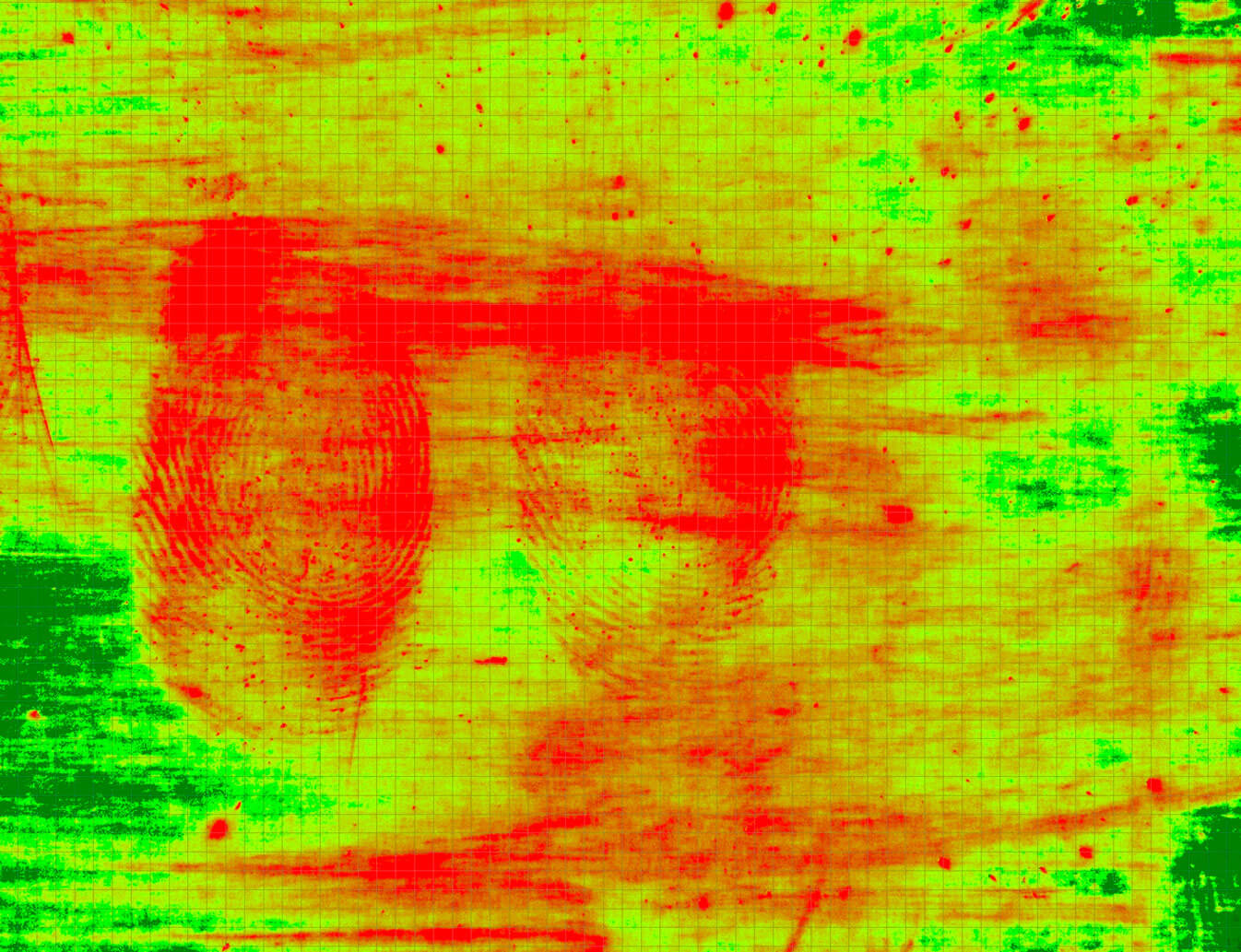

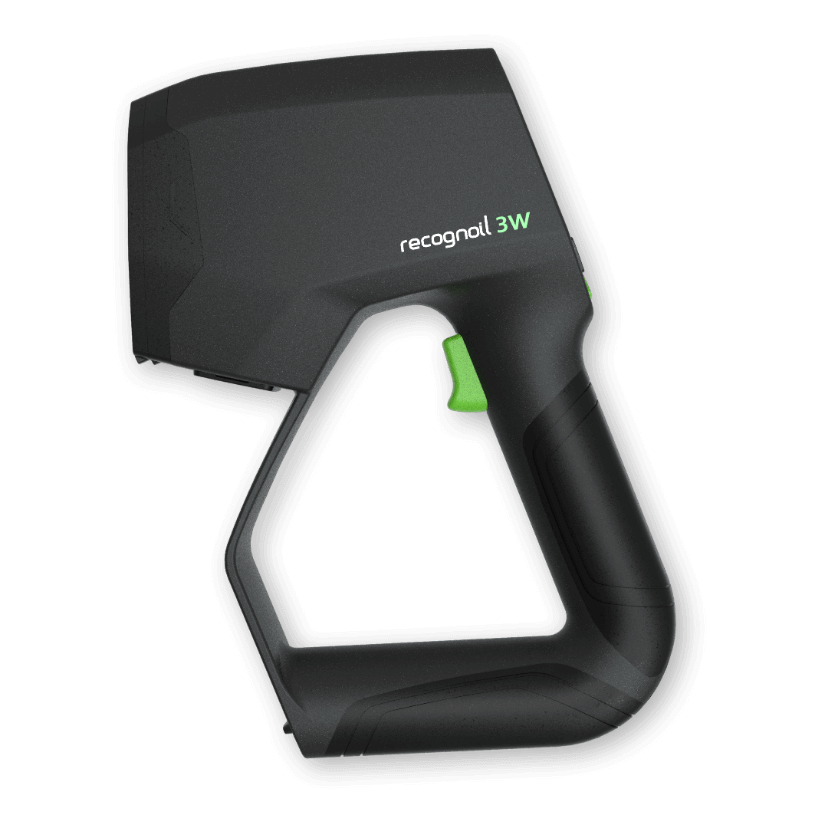

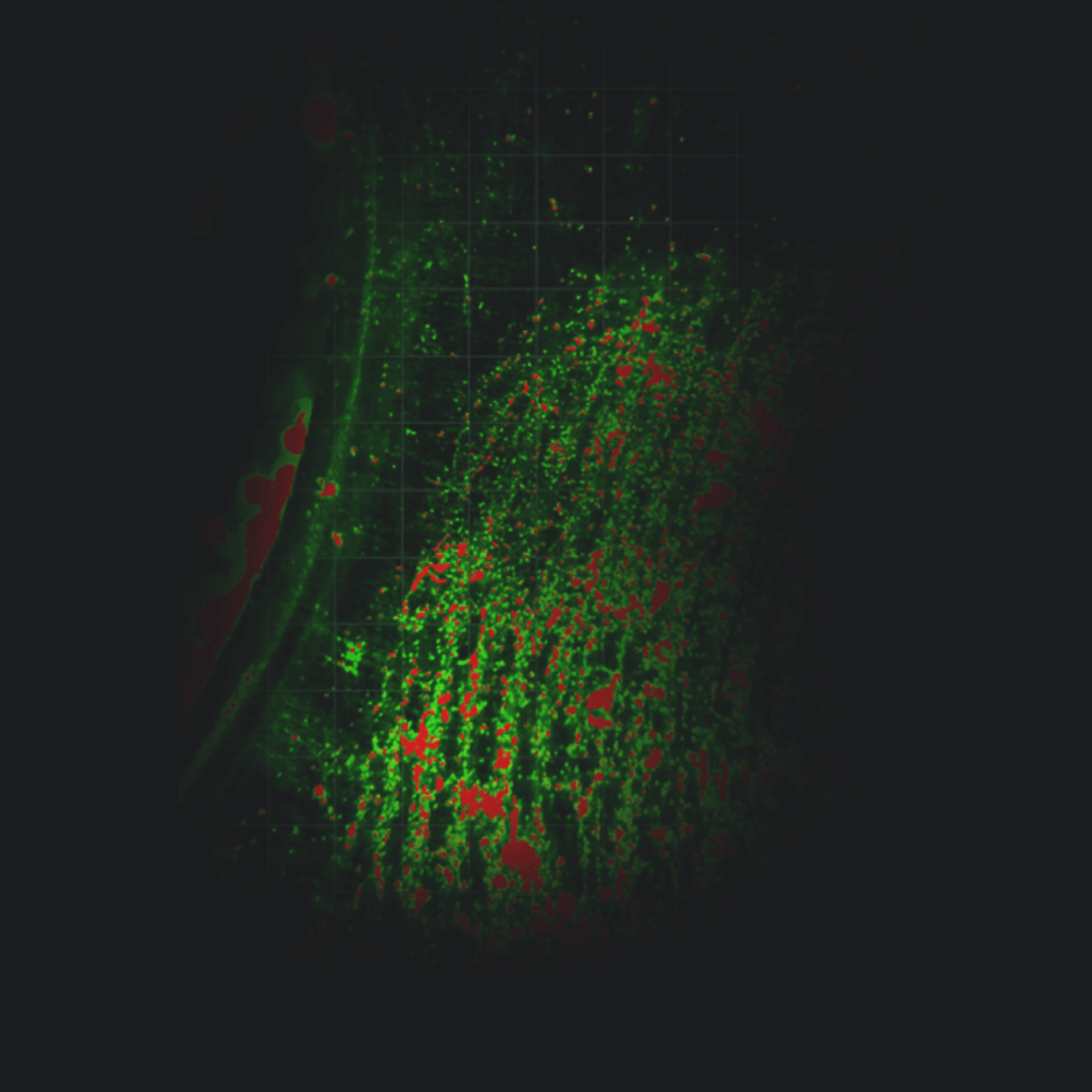

Recognoil® is Czech technology that can detect even the slightest case of spot contamination. It utilizes the revolutionary principle of wide-area fluorescence imaging to detect greasy substances. Our portable Recognoil® 3W device scans the surface, then immediately displays and analyzes the results.

Our customers have been using products from the Recognoil® family for more than 10 years now. Most often they appreciate our products’ ability to help inspect parts for contamination before they undergo subsequent surface finishing processes, or the way they simplify evaluating the thickness and homogeneity of oil films in lubrication and preservation. Recognoil® 3W aids both technologists and managers alike, since it saves resources, lowers part rejection rates and enhances production process quality.

See your products through the eyes of Recognoil® 3W.

Covering

the optical probe

Start using Recognoil® 3W in your own facility. The scanning head of the detector can be fitted with a protective glass cover, so that the active surfaces of the detection head and surrounding optical elements are protected against contamination by undesirable substances and grease.

The device’s scanning head is made from a specialized aluminum alloy, which provides it with longer continuous operation in video mode, increases its detection power and ensures better heat dissipation for the UV emitters.

Secondary

Trigger

Analyze your surfaces from all possible angles, in every possible space. The device has a specialized multi-grip handle, fitted with two trigger-buttons. This way you can easily inspect products hooked onto a conveyor, acquire information above head level, or analyze the surface above an open space.

The design of the Recognoil® 3W device has been coordinated with leading Czech industrial designer Martin Tvarůžek, holder of multiple Red Dot Design Awards. Thanks to this cooperation, the device is highly ergonomic and fully thought-through – carefully considered down to the last detail.

A New Type

Of Analysis

Find out the state of contamination within seconds. Recognoil® 3W can evaluate an area as large as 27 x 20 mm. It is equipped with a white light, helping you to quickly identify the detection zone, and will document everything you need with no preparation required. Furthermore, the device can also read QR codes with settings and preferences, and evaluate other parameters, such as product surface wetting.

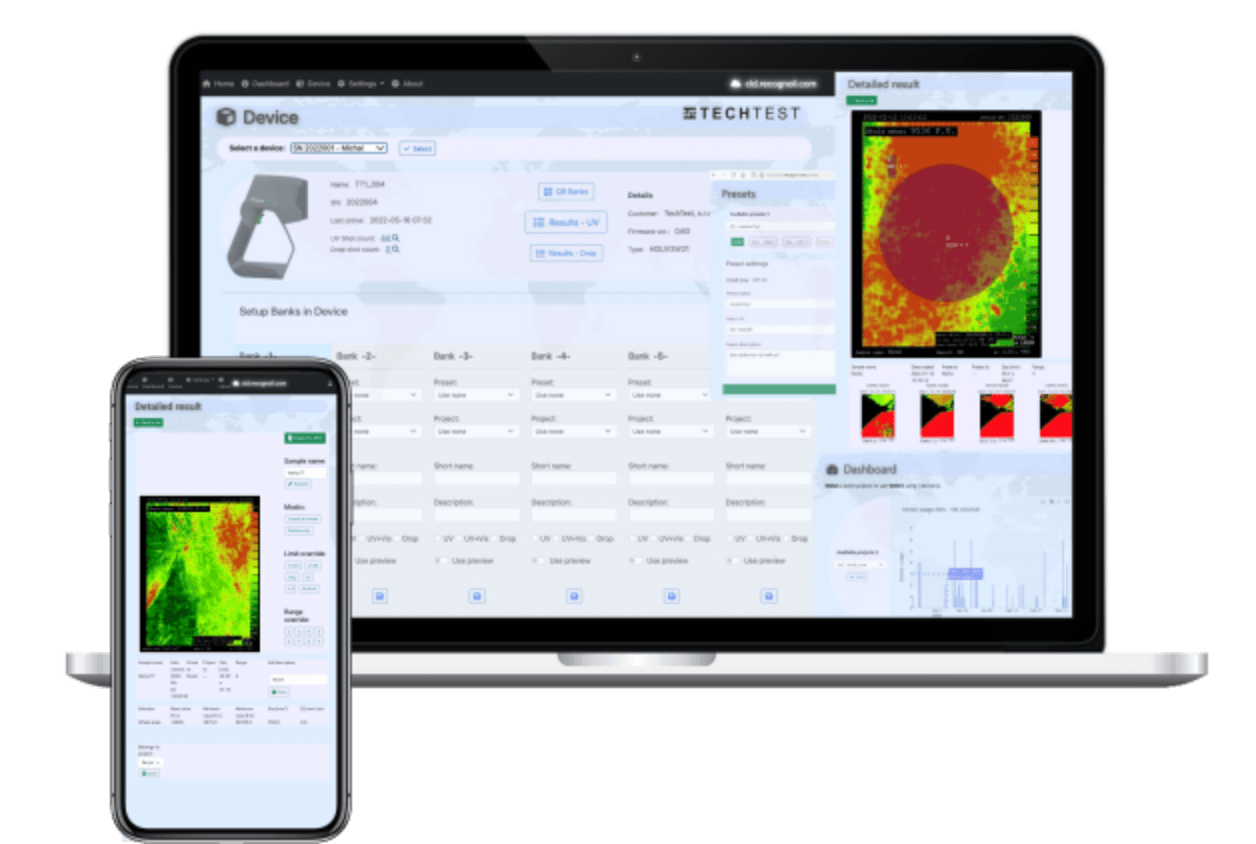

Recognoil® 3W enables you to monitor the quality of production with even greater scrutiny, thanks to a range of analytic methods for you to select. Besides performing inspections to ensure the high purity of various surfaces, it can also monitor surface tension.

Recognoil® 3W easily connects to external probes, which helps with processes like inspecting the inner surfaces of tubes, or similar areas that are difficult to access. Also, with Wi-Fi and Bluetooth, you can connect to other devices that monitor more than just contamination. When evaluating your acquired data, you might also appreciate its Cloud functionalities.

Advantages for a technologist

Are you a technologist or quality specialist? With Recognoil® 3W, you can immediately start streamlining your company’s manufacturing processes

- evaluates a large area in a single measurement

- immediately identifies the critical points of a part

- swiftly reacts whenever the state of a part changes

- operation mode OK–NOK

- detection without pre-processing

- discovers even the slightest of contamination

- uses advanced, feature-packed SW (SW not included in standard delivery)

- performs both quantitative and qualitative analyses

Advantages

for managers

Are you a manager or company director? Don’t miss out! Recognoil® 3W is an investment that quickly pays for itself and more.

- fully professional yet affordable solution

- reduces the rejection rates of your products

- helps you avoid warranty claims

- increases the cost-efficiency of your operations

- easy operation requires little training

- fosters trust and good relationships with customers

- lessens the environmental impact of your business

Comparison With Other Methods

| Recognoil 3W | Surface tension test (ink, markers) |

IR meters | UV spot | UV visual | Special laboratory methods |

|---|---|---|---|---|---|

to fit your needs

| Recognoil 3W | Surface tension test (ink, markers) |

IR meters | UV spot | UV visual | Special laboratory methods |

|---|---|---|---|---|---|

Reference 1

GO Steel Frýdek Místek

For the past 7 years, the excellent output quality of the sheet steel degreasing process at GO Steel Frýdek Místek (formerly Arcellor Mittal) has been the responsibility of Recognoil®. Thanks to regular inspections, the company can now guarantee state-of-the-art quality for its surfaces.

Reference 2

EMEA Doosan Bobcat

At EMEA Doosan Bobcat, Recognoil® is entrusted with random inspections to check the quality of degreasing before products are sent to the paint shop. It also evaluates surface lubrication requirements prior to product assembly.

Reference 3

Everstar

For Everstar, the quality and effectivity of degreasing agents is simply essential. Recognoil® helps fulfill all the quality requirements and important properties of these chemical products.

Reference 4

SpaceX

The American manufacturer of spacecraft, communication satellites and space transport equipment relies on Recognoil® for quality assessment during manufacture.

Reference 4

Cartier

The luxury-brand jewelry maker Cartier pays attention to every detail. Recognoil® enables them to raise the bar of workmanship quality even higher and, as a result, each customer receives a true masterpiece and a lifetime-lasting source of joy.

Reference 4

Škoda

The carmaker Škoda uses Recognoil® as a tool to improve the quality of individual processes used in their production lines. That is our contribution to each new car safely leaving the factory.

Try it out in

your own facility

Still not sure? Need more information? Contact us and we’ll work out whether Recognoil® 3W is the right solution for your business. We’ll calculate the actual profitability of the device given your specific conditions, and even recommend you a suitable measurement procedure.

Contacts

For over 20 years now, we’ve been active in the fields of surface-finishing, surface-preprocessing, engineering, and electrical device design. It’s this experience and expertise which lies at the core of our Recognoil® technology, which has been helping clients for 11 years and counting. The devices we’ve developed have found their application in many places and many industries all over the world.

Ing. Jan Kudláček,

Ph.D

Ing. Jan Kudláček,

Ph.D

Ing. Michal Zoubek

Ing. Michal Zoubek

Projects and cooperation

SIC

Realized projects nurturing innovation and business provided by the Central Bohemian Center of Innovation (SIC): Creative voucher of the Central Bohemian Region, INOvovat – EXpandovat Program and the business development program PLATINN.

B4I

Analysis of business processes, defining areas for deployment of digital technologies, creating a mind map and creating a roadmap for the digitalization project. More Info

EUREKA

Advanced Mechatronic Stamping System with Controlled Lubrication (AMSOL) - Advanced Mechatronic Stamping System with Controlled Lubrication - development co-funded by the Ministry of Education and Science - INTER-EXCELLENCE sub-programme EUREKA - project E!12193.

Recognoil® QB

In addition to Recognoil® 3W, we also offer several other products for wide-area surface scanning and the evaluation of acquired data. Feel free to browse our complete catalog.

Contact us

We’ll gladly give you a demonstration of Recognoil® 3W and show you all the ways it can help you reduce costs and increase your product quality.